Lubrication Equipment

Helping all kinds of industries save money and increase productivity

Lincoln has the right solution for your company, whether it’s manual lubrication, simple automated systems, or large-scale centralized installations. With the BearingSaver® program and our extensive product offerings, we match the correct lubrication or pumping system to every customer and each application. Savings and increased productivity are the tangible results.

Automotive Manufacturing

We lubricate the intricate ballet of robotic activity on the welding line, provide lubrication systems that move with complex conveyors, and help automakers apply adhesives and sealants in numerous applications.

Heavy Industry

Steel, cement, glass, chemical plants, utilities—heavy industry operates in the toughest environments with large-scale lubrication needs. Our systems—which can feed thousands of lubrication points over great distances—offer the most cost-effective answer.

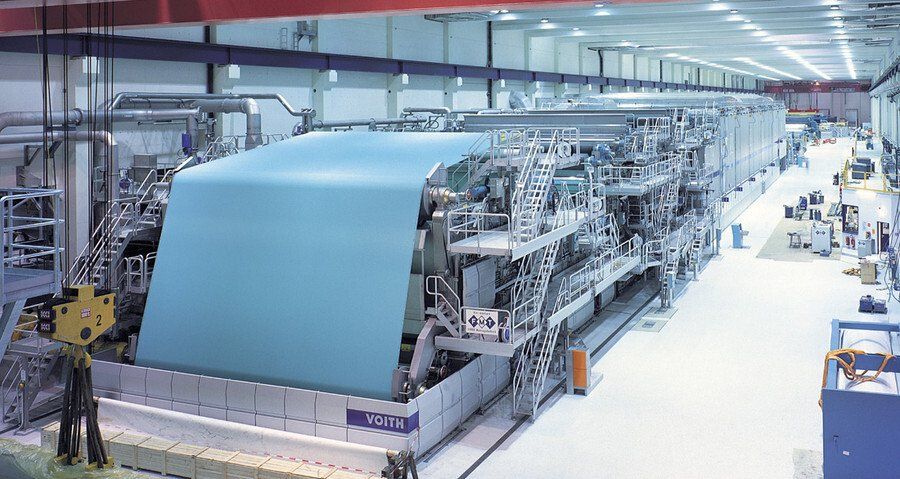

Pulp and Paper

Papermaking machinery operates in a punishing environment of moisture and heat. Our automated lubrication systems eliminate bearing failures and reduce high downtime costs caused by too much or too little lubrication on the paper machine, as well as in the wood yard, debarking area, pulp mill, and bleach plant. Our systems also stop “grease breaks,” paper tears caused by over-lubrication. The result is higher productivity and increased safety for maintenance employees.

Food and Beverage

With complex equipment, difficult environmental factors, concerns about contamination, and extensive use of conveyors, the food and beverage industry has a pressing need for the very best lubrication systems. Lincoln meets the needs of the food and beverage and other industries. Rhein-Main-Sieg, the Coca-Cola bottling plant in Bendorf, Germany, is a prime example. It saves $250,000 a year with a Lincoln automated conveyor-and-machine lubrication system. The installation incorporates centralized lubricant storage and electronic controls that automatically adjust for changes in plant temperature.

Installation and Service

Using our own personnel in concert with fully qualified contractors. We can offer our customers complete “Turn Key” installation of the equipment we sell. This includes aboveground and underground storage tanks, fuel dispensing equipment, consoles and POS systems, canopies, lighting, tank gauges, fuel product piping, shelving/storage rack, mezzanine, modular offices, material handling equipment, paint booths, filter systems, lifts, jacks, and air compressors.

Installation for:

- C-Stores

- Truck Stops

- Service Stations

- Lube Trucks

- Quick Lubes

- Farms Fueling

- Aircraft Fueling

- Service Trucks

- Parts Storage

- Manufacturing

- Auto Parts Manufacturers

- Distribution Centers

- Equipment Dealers

- Automotive Dealers

- Government Agencies

- Municipalities

- Construction Companies

- Utilities

- Mining Companies

- Industries

- Distributors

- Contractors